About

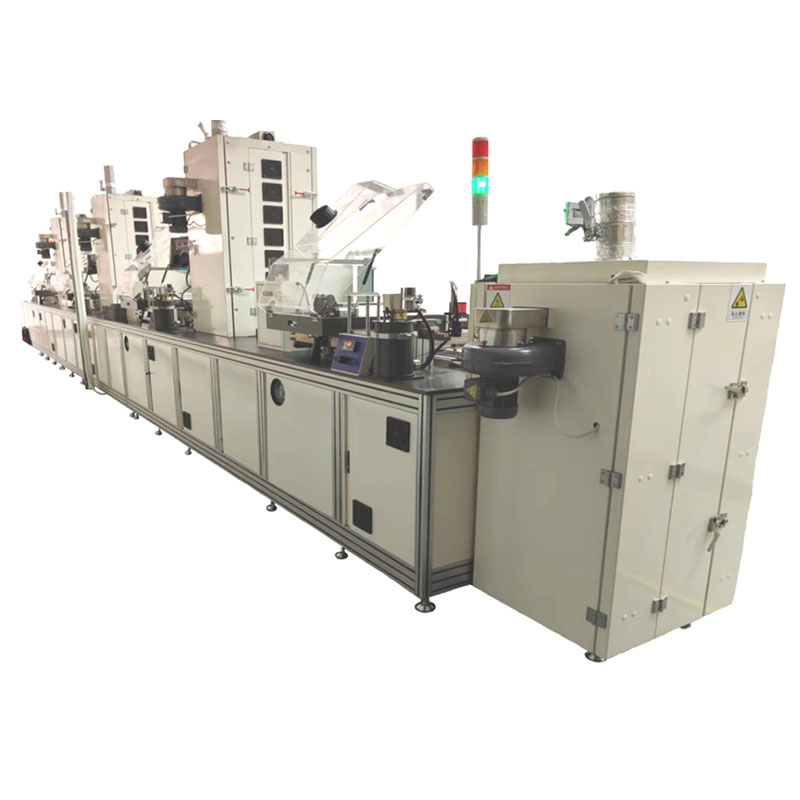

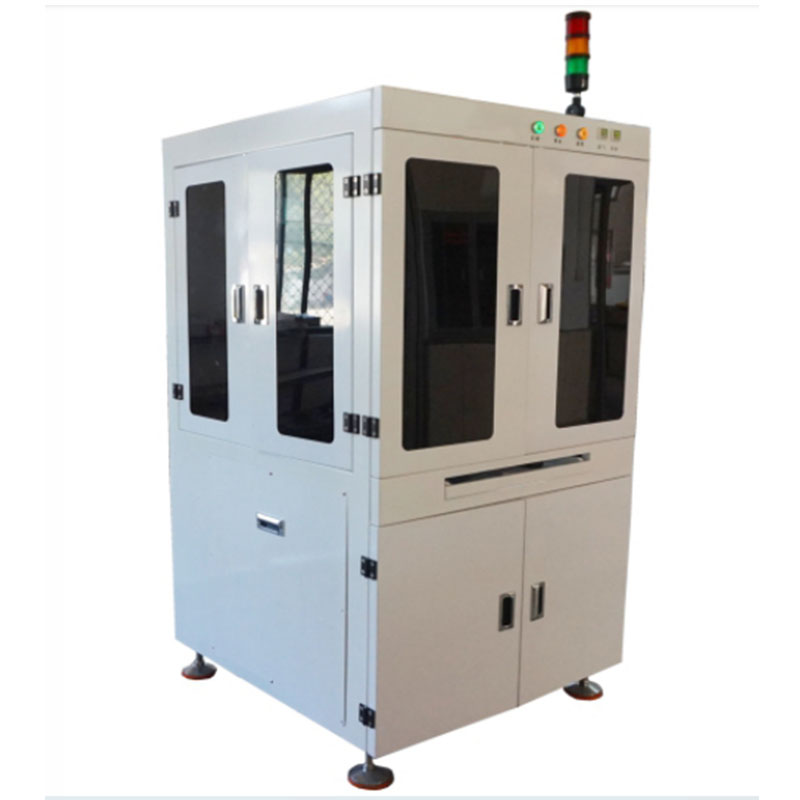

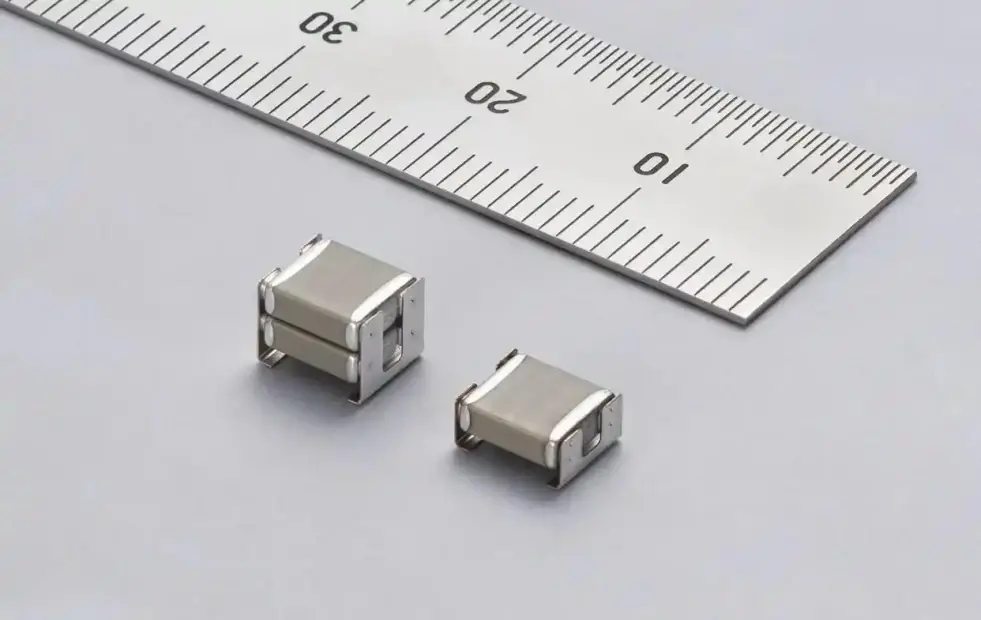

Shuntai Electronic Technology Co., Ltd, We are focusing on the Multilayer Ceramic Capacitors (MLCC),LTCC and HTCC industry,provide leading process equipment and testing equipment; Deeply cultivate solutions for high-precision alignment equipment, electrical performance testing equipment, AI defect detection equipment, etc. Professional technical team, strong production, and strong non-standard equipment design and production capacity, serving well-known clients both domestically and internationally.