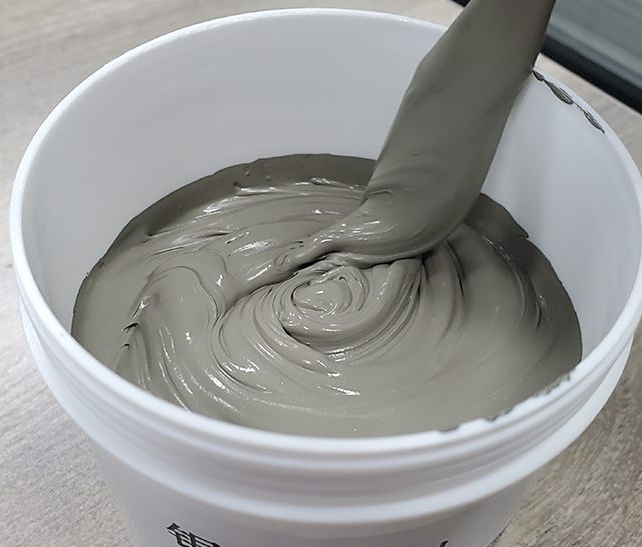

This silver paste product designed for application to the external electrodes of MLCCs terminals. Silver gray paste like fluid, mainly composed of silver powder, glass powder, and organic binder.Does not contain prohibited substances such as lead, cadmium, hexavalent chromium, etc., meets the environmental requirements of RoHS directive, and is applied to Class I and II capacitors.

Product Specifications:

| Solid Content(%) | Viscosity (Kcp) | Fineness(90%) | Applicability |

| 78±1.5 | 23.0±5.0 | ≤10.0 μm | Class I and II |

(Please Note*:The viscosity detection conditions: Brookfield HBDV- Ⅱ +,CP52, 25±0.5℃, 10rpm)

Product Features:

◆ After sintering, the silver layer at the end is dense

◆ Excellent electrical conductivity

◆ After sintering, it adheres tightly to the ceramic body and has high adhesion

Recommended process:

| Stiring | Slowly stir evenly before use |

| Termination | Terminal the end with matching equipment and technical parameters |

| Dry | Chain type oven (with moderate ventilation) at 100-150 ℃ (peak temperature), 20-30 minutes (full process time) |

| Sintering | Chain tunnel furnace with sufficient ventilation to ensure complete decomposition of organic systems. Suggest based on the ceramic body select the specific sintering temperature for the system. The recommended sintering conditions are as follows Sintering temperature (℃):750±10; Peak time (min): 10-15; Total duration (min): 60-75 |

| Termination Plating | Suitable for amino sulfonic acid plating system |

| Clean | Suggest using anhydrous ethanol |

| Storage | Store in a cool place but do not need to be frozen. The optimal storage temperature is 18-25 ℃. |

| Shelf Life | 6 months (stored below 25 ℃) |

| Packaging | 500g/bottle or 1000g/bottle or 1500g/bottle. |

Usage and precautions:

● The paste meets the requirements of standard sealing and immersion coating technology, and appropriate sealing parameters can be adjusted according to actual needs.

● Stiring the paste thoroughly before use, but the speed should not be too fast, otherwise air will in and produce bubbles. The stirring time is 3-5 minutes. It is recommended to use a stainless steel knife without a sharp blade for stirring, to avoid scratching the inner wall of the silver paste bottle. It would be better if the paste can be slowly ground for 6-8 hours the day before production, with a speed of 0.5-1 revolutions per minute.

● The temperature and humidity of the paste usage environment should be relatively stable. It is recommended to control the optimal range of temperature and humidity as follows:

(1) Temperature: 18-25 ℃, (2) Humidity: 50-70% RH.

● Choose solvent resistant scrapers, such as polyurethane (PU) scrapers (60-75 hardness), otherwise scraper corrosion or expansion may occur; After the scraper is put into use, it should be regularly checked for deformation. If there are any abnormalities, they must be replaced in a timely manner to avoid inconsistent printing patterns.

● Immediately put it into the drying oven after termination dipping, and maintain good ventilation conditions in the drying oven; It is recommended to choose low-temperature slow drying method for drying.

It is a low-temperature curing silver paste product used for external electrodes of MLCC (0402 size and above) soft terminals. This product has a complete paste morphology in dipping process, no defects, and the soft end electrode is firmly attached to the end electrode without easy detachment. It has good conductivity, strong bending resistance, and strong reliability.

The red paste like fluid is mainly composed of copper powder, glass powder, and organic binder. It does not contain prohibited substances such as lead, pot, or hexavalent chromium, and meets the environmental requirements of the ROHS directive. Usually be used in MLCC as an end electrode. This product has excellent performance, with a complete and defect free paste morphology in dipping process. After sintering, it can form a dense copper layer, preventing the invasion of Ni plating solution during electroplating; At the same time, this product can minimize the occurrence of pinholes at the end, thereby improving the reliability of MLCC products

This series of products is applicable to the production of MLCC products. Gray black paste like fluid, mainly composed of nickel powder, organic resin, and organic solvent. Nano-sized nickel powder is easy to agglomerate, the internal electrode may appear electrode discontinuity and unevenness after sintering, therefore this nickel paste with good dispersion and stability has been developed. It shows good adhesion with the dielectric layer after stacking and good electrode continuity and flatness after sintering, greatly improves the reliability and compressive strength of MLCC. The shrinkage matching, crack, yield and reliability can be improved by adjusting the additives.

Silver-Palladium Paste is applied to the internal electrode printing of MLCC products. A grayish-black, paste-like fluid primarily consisting of palladium silver powder, organic resin, and organic solvent. It features good dispersion without agglomeration; excellent printing characteristics without erosion to the dielectric layer; strong adhesion that effectively solves the cracking problem caused by the paste; and a flat and continuous metal layer after sintering. It does not contain harmful substances such as Pb, Cd, etc. (meets RoHS 2.0 requirements), and can be customized with different silver-palladium ratios based on customer needs.