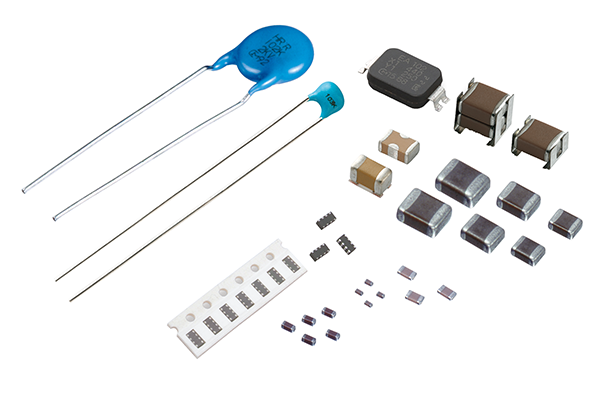

Introduction to MLCC High-Performance Products

The tiny MLCC is not only the industrial rice, but also plays an indispensable role in military equipment as they become increasingly electronic. As electronic devices evolve towards miniaturization and high performance, MLCC faces more severe working environments, including challenges such as mechanical stress and thermal shock. To address these challenges, different design types of MLCC have emerged.

Conventional MLCC

MLCC adopts a standard multi-layer structure design, usually consisting of a ceramic body, inner electrodes, and outer end electrodes. The terminal electrodes generally include copper and nickel plating layers, which have cost advantages but are prone to cracking under mechanical stress.

Soft terminal MLCC

The terminal electrode structure of soft terminal MLCC is different from that of conventional MLCC, as a conductive resin layer is added to the external electrode. Ordinary terminals have a three-layer structure of copper, nickel, and tin, while resin electrodes have a 4-layer structure with a conductive resin layer added between copper and nickel. This conductive resin layer can relieve external stress, has good bending strength, and thus avoids cracking.

Open mode MLCC

Open mode MLCC is designed specifically to solve mechanical crack problems, characterized by a different design of the overlapping area (active area) of the internal electrodes, which can reduce the risk of short circuit even when cracks occur.

Open mode MLCC +Soft terminal MLCC

On the basis of open design, the external electrode is made into a soft terminal structure, greatly reducing the risk of cracking, but the cost is relatively expensive.

Internal string structure MLCC

The internal structure is designed as a series structure to reduce the risk of capacitor failure, usually used in high voltage and low capacitance designs.

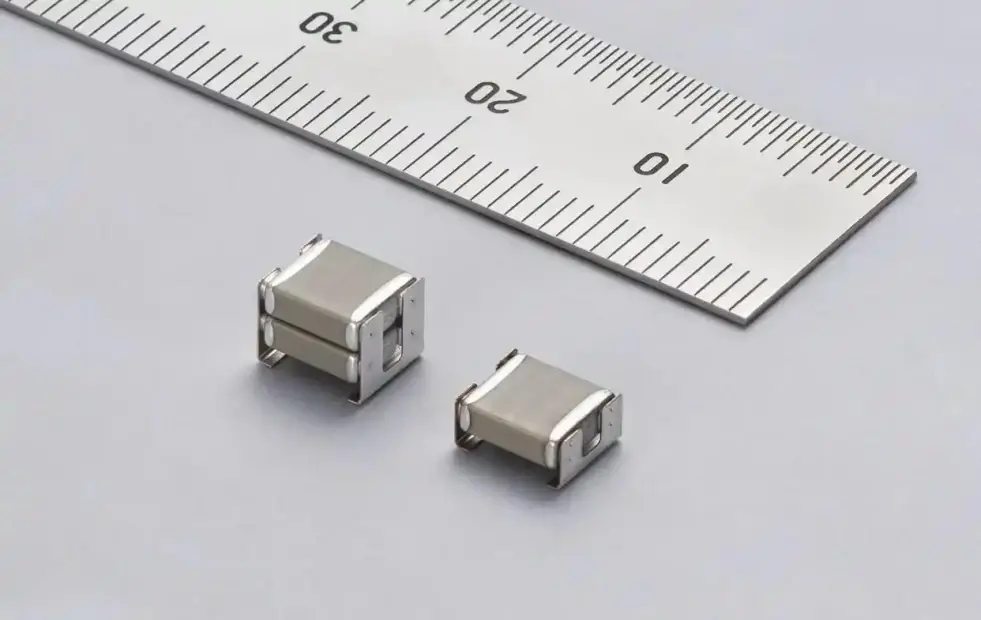

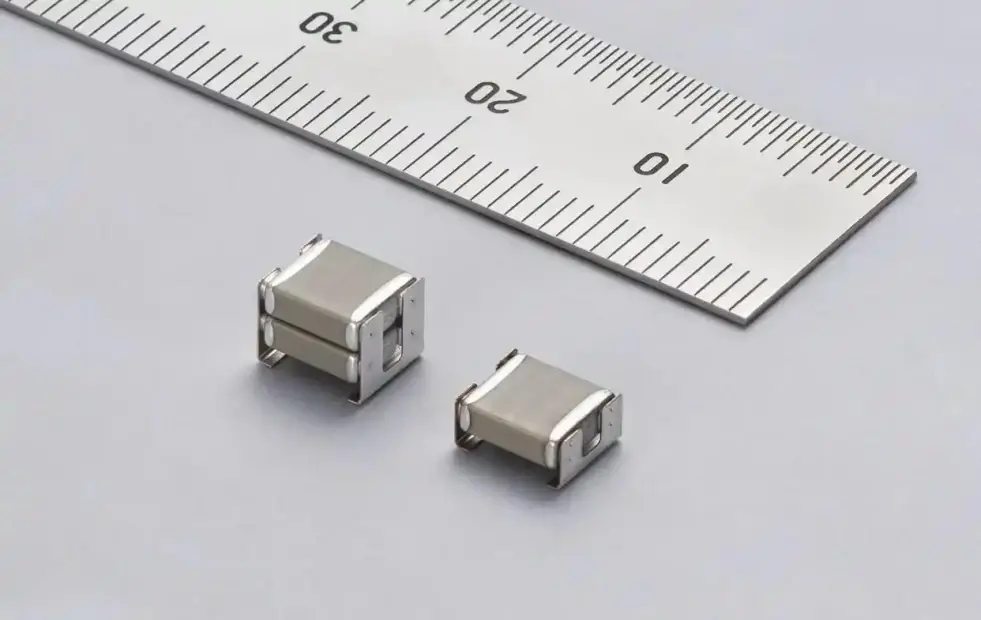

Bracket MLCC

MLCC with metal brackets enhances mechanical strength, improves vibration and impact resistance by adding a metal frame, making it suitable for high reliability applications.