MLCC Production Efficiency Doubled, Six-Sided Appearance Inspection Equipment

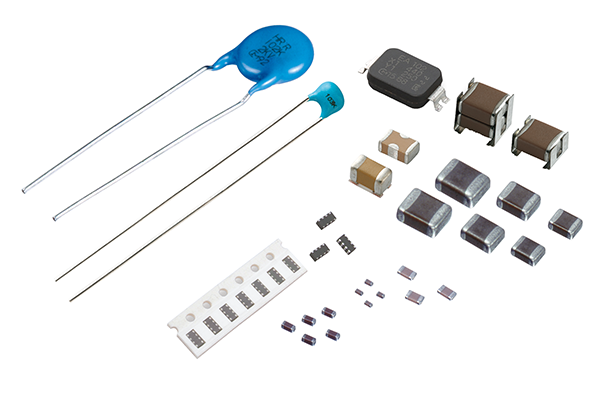

In the manufacturing process of MLCC (Multilayer Ceramic Capacitor), appearance inspection is a critical quality control step to eliminate products with surface defects or dimensional abnormalities, thereby ensuring their performance and reliability. Due to the extremely small size of MLCC components, manual inspection requires the use of microscopes, and visual inspection is prone to deviations and inefficiency.

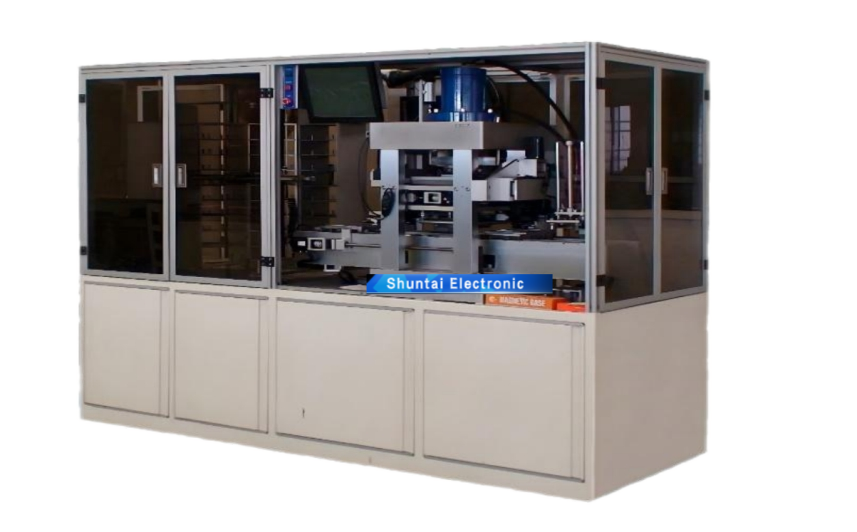

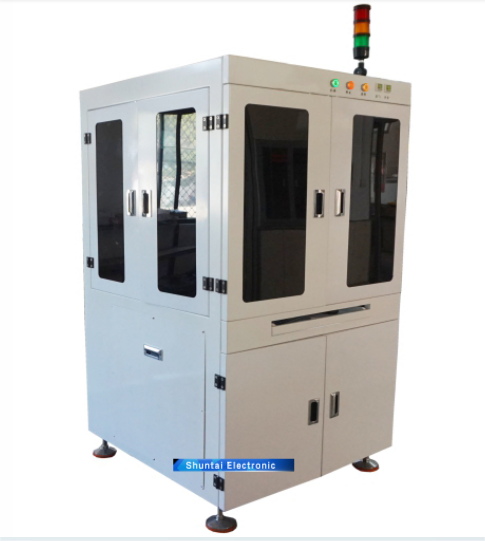

The six-sided appearance inspection equipment integrates technologies such as computer vision, image processing, and artificial intelligence. It enables rapid and accurate inspection of all six sides of MLCC products, utilizing algorithms for analysis and judgment to precisely screen out non-compliant products. Inspection items include electrode dimensions, ceramic body dimensions, scratches, cracks, chips, discoloration, micro-cracks, and other defects on MLCC products. The recognition efficiency can reach 8,000–13,000 pieces per minute.

High-precision inspection technology can effectively detect product defects and abnormalities, improving product quality. By automating the inspection process, it reduces manual operations while enhancing production efficiency and output.