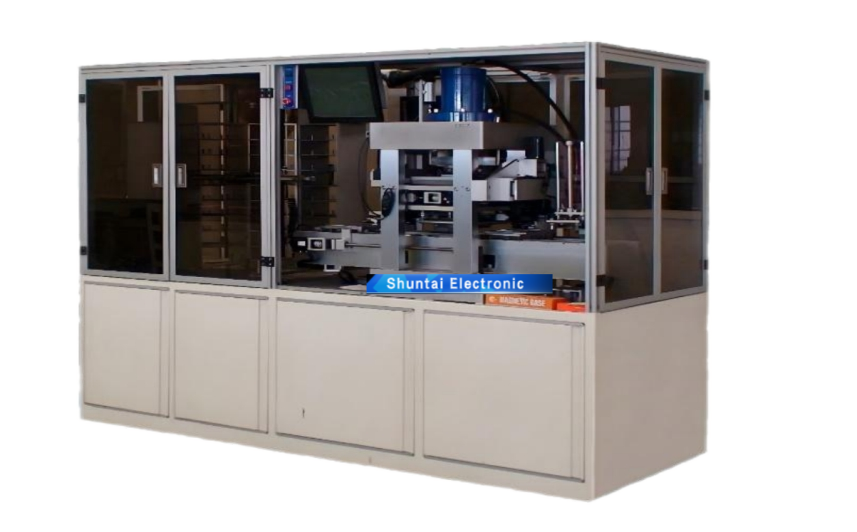

Main Features:

◆ Fast machine start up, simple operation, high alignment accuracy, small footprint and numerous possible options

◆ A stable servo pressure system ensures stack quality

◆ Stacking sequence such as pressing forces and pressing times per each layer can be fully programmable via a touch screen interface.

◆ Permission management control, real-time display of device operation, shutdown, and alarm indicator lights

Technical Specification:

| Model | Automatic Stacker |

| Loading and Unloading | Manipulator |

| Alignment | CCD alignment after pre alignment |

| Removes carrier film | Carrier film can be removed automatically before or after taking |

| Bar Carrier | Vacuum platform adsorption Or Trays |

| Stacker Press Force | 1,000kgf~20,000kgf (MAX 196KN), (optionally) |

| Press Force Precise | ±2%( test as 10,000kgf ) |

| Stack Thickness | Max 5 mm(1000 layer) |

| Stacking Temperature | MAX: 100℃ ±3% |

| Stacking Table | Plane accuracy:±0.01 mm; |

| Alignment Platform | Stacking and pressing area: 230mm, Can be customized Drive accuracy:±2 um |

| Options | vacuum pump, Sheet glue applicator, Automatic visual tape inspection systems to detect pinholes, Custom designs to meet special requests for your technology |