Advantages and Classification of Isostatic Pressing Machines

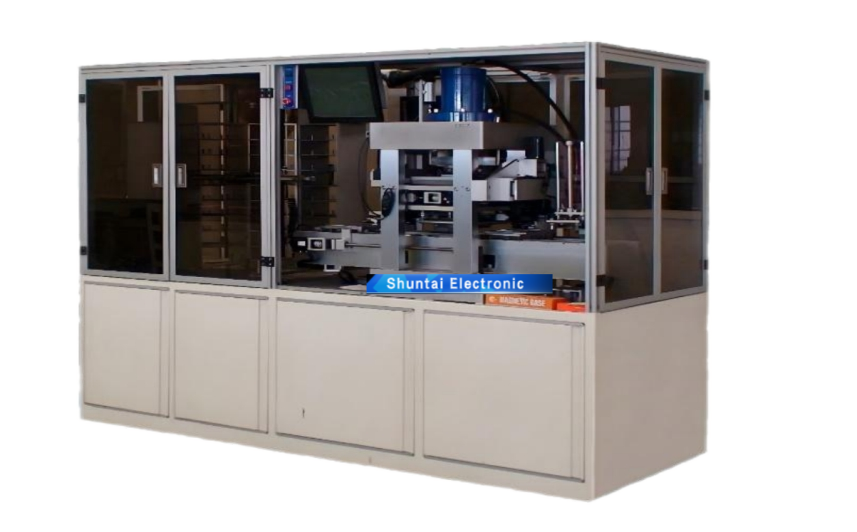

The isostatic press is based on Pascal's principle and is used for forming various powder products under ultra-high pressure conditions. The resulting products exhibit excellent isotropic properties, making them particularly effective for components with high-performance requirements, complex shapes, and large length-to-diameter ratios.

The advantages of isostatic presses include: technological advancement, energy efficiency, low failure rate, operational stability, ease of maintenance and repair, long service life and durability, and uniform density of pressed compacts.

Isostatic presses are mainly classified into three types: hot isostatic presses (HIP), warm isostatic presses (WIP), and cold isostatic presses (CIP).

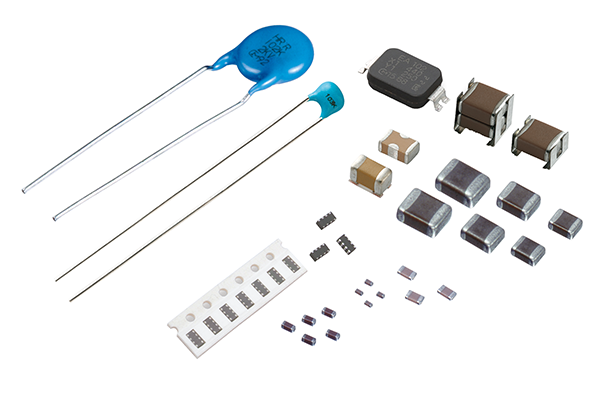

1. Hot Isostatic Pressing (HIP) is an advanced sintering process. The product is placed in a sealed container, subjected to uniform pressure from all directions, and simultaneously exposed to high temperatures. Under the combined effect of high temperature and pressure, the product undergoes sintering and densification.

2. Warm Isostatic Pressing (WIP) utilizes the principle of equal pressure in all directions within a liquid medium to achieve uniform pressure compaction of powder materials. It employs a PLC-based electrical control system to manage the operation of heating, filling and draining systems, intensifiers, hydraulic stations, and other actuators, thereby enabling precise pressure control within the ultra-high pressure working cylinder.

3. Cold Isostatic Pressing (CIP) technology involves using rubber or plastic as mold materials at room temperature, with a liquid as the pressure medium. The typical working pressure ranges from 100 MPa to 630 MPa. Sweden was the first country in the world to successfully research and produce isostatic presses, and its products are known for their high quality and substantial export volume.