Key Technologies for High-Capacity MLCCs – Stacking Process

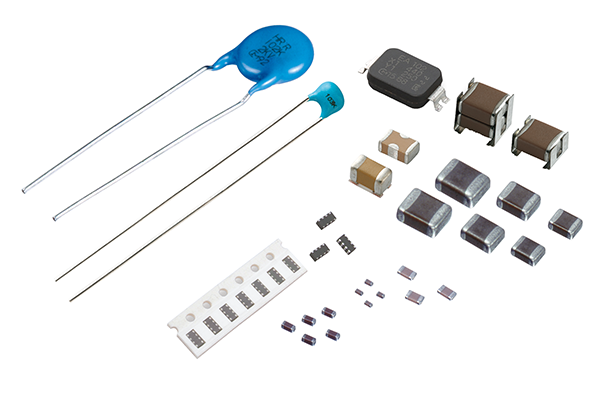

With the rapid development of the electronic information industry, communication devices such as electronic computers, mobile terminals, and smart wearables are becoming increasingly miniaturized and multifunctional. To meet these demands, multilayer ceramic capacitors (MLCCs) are also continuously advancing toward miniaturization and higher capacitance.

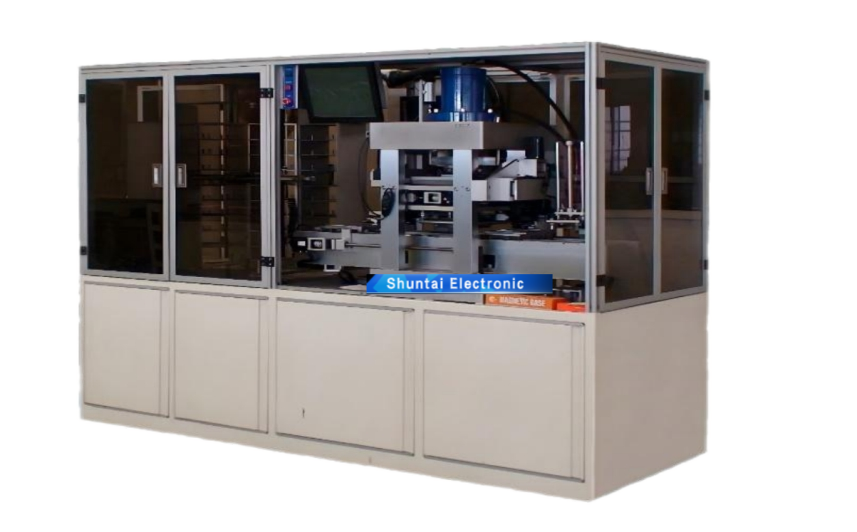

1.The working principle of stacking equipment

Stacking equipment mainly completes processes such as pattern cutting and peeling, stacking electrode patterns according to process requirements, and laminating capacitor raw materials. Its working principle is: the equipment unfolds the thin film with silk screened electrode patterns under a set constant tension, cuts the thin film electrode patterns to a specified size, uses a specific workbench to vacuum adsorb and peel off the film, scans and positions it through an image positioning system, and then transports it to a predetermined stacking workbench. The film is stacked on the positioned carrier plate, and the pattern is displaced according to the product production process to form two electrodes. The required number of layers of capacitor raw materials are stacked with pre pressure, and then the carrier plate and capacitor raw materials are sent together by a conveying mechanism to the protective film covering station to add a protective film, and then sent to the compaction station to apply high pressure. Maintain pressure for a certain period of time to make the structure of the capacitor material dense, Finally, it is sent to the receiving box for material collection, completing the entire work cycle.

2.Difficulty of MLCC Stacking Process

With the miniaturization and high capacity development of MLCC, the technical difficulty of its stacking is very high, mainly including the following difficulties:

1) When peeling the film from the PET carrier tape, the peeling effect of the stacking equipment on the dielectric film is an important prerequisite for achieving precise alignment of the internal electrodes. There are generally two situations where the peeling effect is not good. One reason is that the film is torn and cannot be completely peeled off. The second issue is that although the membrane is completely peeled off, the suction plate of the stacking equipment does not firmly adhere to the membrane, causing slight wrinkling of the membrane adsorbed on the suction plate and displacement of the internal electrode alignment after stacking, known as stacking displacement phenomenon. The dielectric film used in larger MLCCs is generally thicker, stronger, and less prone to tearing, while in micro MLCCs, due to size limitations, the dielectric film is thinner and has lower strength, making it easy to tear when subjected to uneven force during peeling.

2) When the dielectric film is several μ m thick, the thickness of the printed inner electrode is close to that of the dielectric film. The influence of the thickness difference between the areas with and without inner electrodes on the dielectric film cannot be ignored, and the "step effect" becomes significant. Due to the small electrode pattern area of the micro MLCC screen, the blank area around the electrode pattern area is relatively large. When peeling off the dielectric film, the blank area is in a micro suspended state under the "step effect", so the suction force of the suction plate on the edge area of the film is relatively insufficient, which is prone to peeling failure.

3) Due to the significant reduction in the size of the internal electrodes in micro MLCCs, and the unsuitability of excessively reducing the size of the chip's margins (i.e. the blank areas without printed internal electrodes) to ensure sufficient cutting process margin, the area proportion of a single internal electrode in the chip is significantly reduced. The problem arising from this is that when stacking dielectric films with internal electrodes printed on them, the contact surface between adjacent films is small, and the bonding is not strong enough, which can easily cause relative sliding and displacement.

3.The impact of stacking on the capacity of MLCC

Stacking is the process of stacking ceramic film sheets with printed internal electrodes in a staggered manner according to design requirements, forming a block. The alignment accuracy of the stack will directly affect the facing area of the upper and lower electrodes, thereby affecting the capacity of the product.